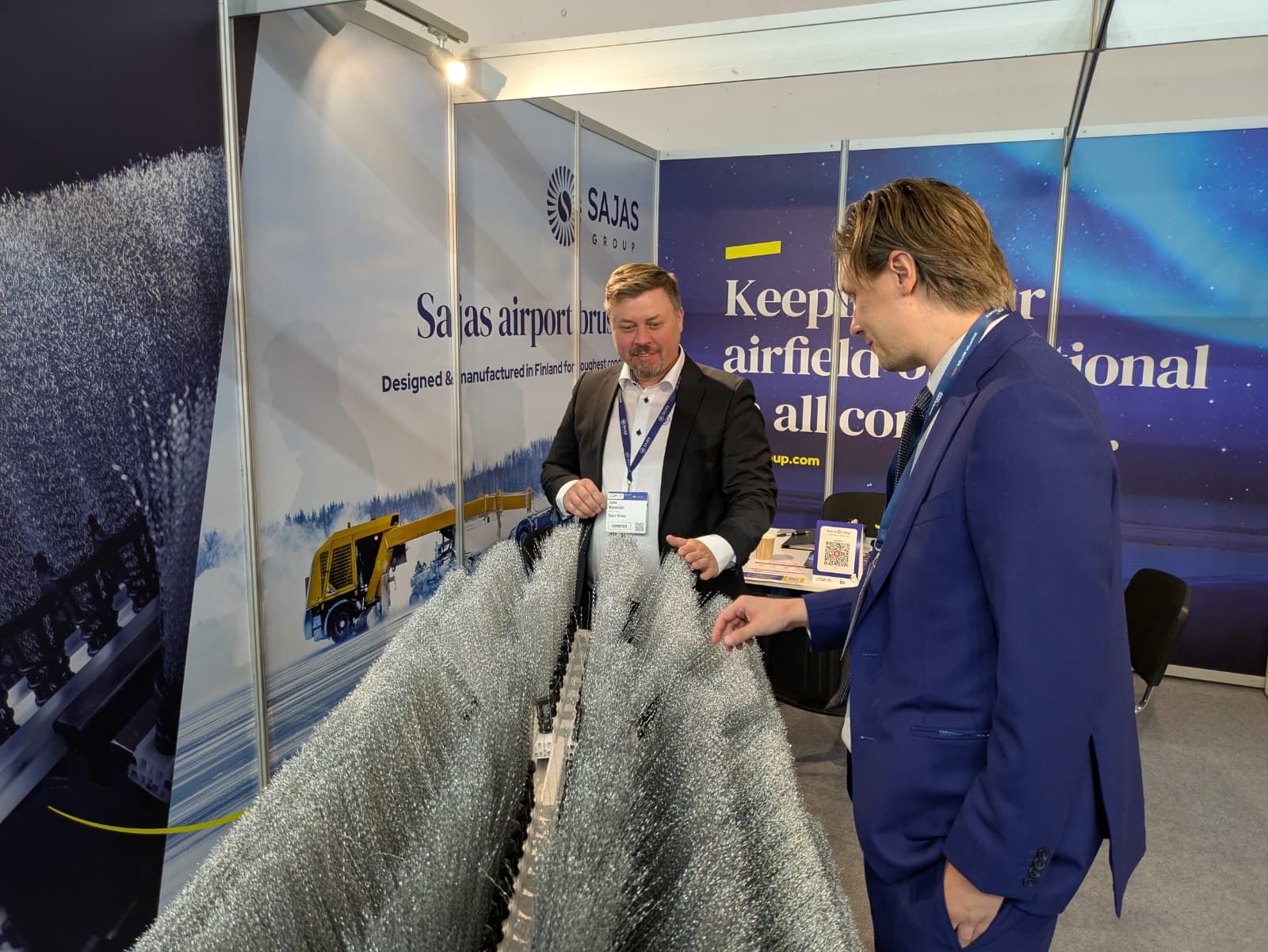

Keeping runways clean and safe: interview with Juho Kannisto, Sales Manager for Airport solutions

Airport brushes have long been a key pillar of the Sajas product portfolio. Airports are among the most demanding environments imaginable: their equipment must operate flawlessly in freezing temperatures, meet strict aviation safety standards, and never fail in critical conditions.

To shed light on what makes airport brushes such a specialised field, we spoke with Juho Kannisto, Sajas’ Sales Manager for Airport solutions.

How do the requirements for airport brushes differ from other types of brushes? Safety must be the number one priority?

Absolutely. Products used in airports must comply with aviation regulations, especially regarding material selection and durability. Our brushes are designed to withstand intensive use without breaking.

Specifications also require that the brushes perform reliably at -40 °C. The materials must remain flexible and not become brittle in operation in extreme cold.

Airport sweepers need to do their job as quickly and efficiently as possible to ensure smooth air traffic even in winter conditions. Consequently, the brushes also need to be quick to replace. In operation, the brushes spin at up to 900 RPM, so they must endure heavy mechanical stress. A broken brush could even pose a safety risk if any debris ends up on the runway as so-called FOD – foreign object debris.

What needs to be considered when designing and manufacturing airport brushes?

Material selection is crucial. The brushes must last their whole service life without breaking.

At northern airports, steel wire is typically used instead of plastic bristles, as in typical street sweeping. The steel must meet specific chemical composition requirements to ensure durability.

Customers also expect consistent performance: brushes must not wear out too quickly. Typically, steel brushes at airports last about 100 hours before needing to be replaced.

Conditions at northern airports differ greatly from those in warmer regions. How do these differences affect the brushes? Are there other special environments you need to adapt to?

Northern airports mainly use steel wire brushes, but there are exceptions. Some military airfields in regions where frost is rare prohibit the use of steel brushes and rely on plastic ones instead, as they mainly face water and slush rather than ice and snow.

In Finland, airport operator Finavia maintains 20 airports, two of which are reserved for the Defence Forces and four are so-called joint-use airports serving both civil and military aviation. The same steel brushes are in use in both civil and military airports.

Sajas has long collaborated with Finavia and equipment manufacturer Vammas in airport brush development. How did this cooperation start?

Sajas has been manufacturing brushes for airport use since 1975, originally for the Finnish Civil Aviation Administration, today called Finavia. From the start, we developed the products together with machine manufacturers to meet the local conditions.

Initially, steel brushes were produced as ring-type brush segments and later as tufted brushes, which provided better sweeping results. These were eventually replaced by the current cassette-type brushes for greater efficiency and easier replacement.

Vammas, originally operating under Finland’s Ministry of Defence, has changed ownership several times and is now part of Vitera Oy. We supply all first-installation brushes for new Vammas sweepers.

Our collaboration has included adapting our products to the specifications of different sweeping machines and developing our own production technology to meet those needs. Many of our manufacturing machines are designed and built in-house specifically for this purpose.

Product development has continued throughout the collaboration, including materials and other properties. Each year, new sweeper models enter the market, and we are always ready to provide a compatible brush solution, even if the machine came with a competitor’s brushes.

How would you compare Sajas airport brushes with the competition?

Our main advantage is flexibility. We can manufacture brushes to fit any sweeper on the market.

Customisation and adaptability are our strengths, whereas many competitors offer only standard-length or otherwise limited products that may not be ideal for the end user.

All our brushes are designed to operate reliably down to –40 °C without breaking.

Sajas recently introduced the new CoreFit Cassette System. Can you tell us more about it?

The CoreFit Cassette System is our way of offering a custom-fit solution for every sweeper model our customers have in use. Sweepers from different manufacturers may vary, since they are built to match each customer’s requirements, such as working width.

We deliver our brushes as machine-specific sets, ready for installation. Maintenance staff only need to swap the cassettes on the spot, and the machine is back in operation quickly.

Some competitors also supply sets, but their cassettes come in a few fixed lengths that rarely match the core exactly, so installers must use filler pieces or cut them to size. CoreFit eliminates all that.

Airport products must meet strict technical standards. Do airports also set specific requirements for suppliers?

Indeed. An airport is a highly regulated environment where safety is built into every operation. This also means that service providers’ employees must be familiar with the airport’s rules and procedures.

We must also stay in constant contact with our customers and anticipate their needs. Since most airports operate 24/7, there is no room for downtime; brushes must always be available and functional. Nordic airports, in particular, take pride in keeping their runways open year-round, regardless of the weather.