Sustainability at Sajas Group

Sustainability at Sajas begins with the choices we make in product design and manufacturing. Our brushes are built for long service life, efficient material use, and reliable performance in demanding environments.

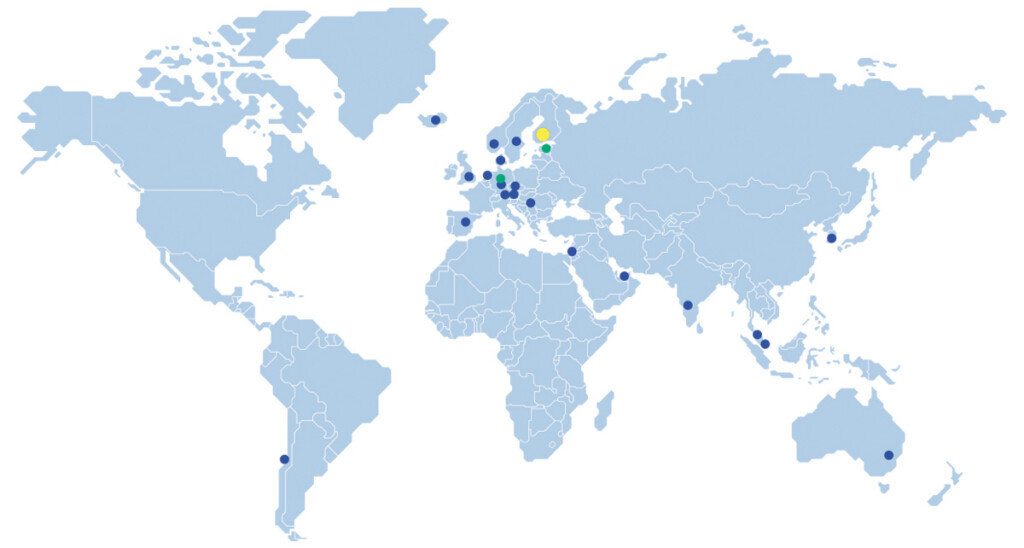

Beyond our own operations, our products contribute to safer transport infrastructure and cleaner urban environments by helping keep streets, railways, airports, and drainage systems functioning as intended.

As part of the Lagercrantz Group, we follow a structured ESG approach that guides our environmental, social, and governance practices.

Environmental responsibility

Our most significant sustainability impact comes from the materials we use and the way we engineer our products.

Sustainable materials

Bioline

In 2025, we introduced Bioline, a biodegradable tuft material developed for selected brush types. Bioline reduces dependence on fossil-based raw materials and offers a more environmentally friendly alternative for sweeping applications. Our first brush using this material is Turboline.

Bio-based material development

We continue to investigate renewable and recyclable raw materials to expand our range of sustainable product options.

Recycled polypropylene

We have invested in equipment that allows us to re-granulate and internally reuse all surplus polypropylene (PP) generated during production, ensuring none is wasted.

Reduced plastic content

Where suitable, we minimise plastic use by incorporating plywood structures into components such as gutter brush bodies.

Recyclability

All PP-based products can be recycled as energy waste in accordance with Finnish and European waste-handling practices.

Product design for long service life

Long-lasting products require fewer replacements and reduce total resource consumption.

Our Finalon and Finalon+ fibres are engineered for durability, ensuring consistent performance even in heavy professional use. Their long service life helps reduce waste and supports more sustainable operations for our customers.

Modular and low-waste solutions

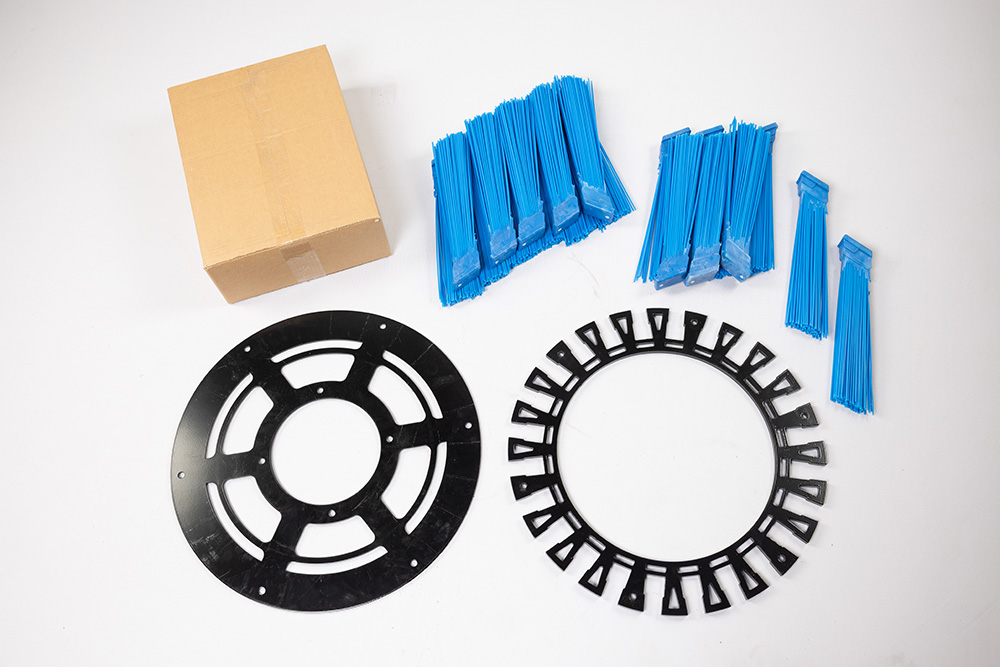

Turboline

The Turboline modular gutter brush system features a mounting plate that remains on the machine, and replaceable tufts. Only the worn elements need to be replaced, reducing waste and lowering transport and storage requirements.

CoreFit Cassette System

The unique CoreFit Cassette System eliminates material waste in demanding airport maintenance by providing cassettes that always match the machine core length.

Brush rings

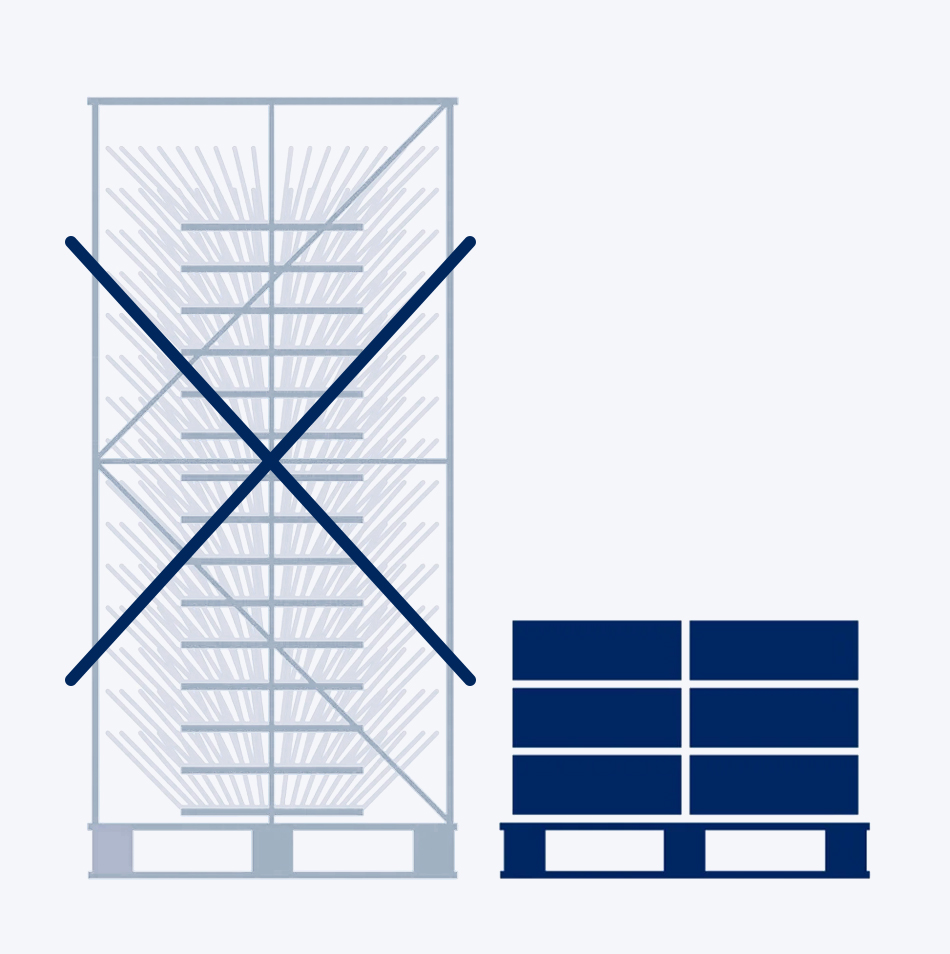

Our brush ring products are designed for efficient logistics. Their compact form and packaging reduce transport emissions and simplify warehousing.

Across our product families, the principle is the same: replace only what is necessary, and retain what still works.

Resource and energy efficiency

Our production facilities operate entirely on renewable electricity, further reducing the environmental footprint of our manufacturing.

We also improve resource efficiency through:

- recycled PP packaging made from our process surplus

- transport-optimised, reusable and recyclable pallets

- compact product designs that minimise transport volume

Social responsibility

We aim to provide a safe, inclusive, and responsible working environment for our employees and partners.

- Continuous improvements in workplace safety and ergonomics

- Company-wide health and well-being initiatives

- Equal opportunity and diversity across all levels of the organisation

- Long-term cooperation with suppliers who share our sustainability values

Governance

As part of Lagercrantz Group, we follow clear governance principles and strict ethical standards.

- Ethical and transparent business practices

- Compliance with applicable regulations

- Transparent reporting of financial and sustainability performance

- Supplier Code of Conduct

- Supplier assessments based on environmental and ethical criteria

- Ongoing sustainability development work, including the creation of a structured sustainability roadmap