Why brush fibre quality makes all the difference

In any technical brush, the single most important element isn’t what you see from the outside. It’s the fibre. Fibre quality is what determines how a brush performs in practice: how well it sweeps, how long it lasts, and what kind of results it delivers.

That’s why, at Sajas Group, we don’t want to leave this to chance: we make our own fibre.

A capability few others have

We have been manufacturing most of our own filament, the fibre for our brushes, in-house for over 40 years. The process is technically demanding and requires not only specialised equipment, including ovens, cooling baths, stretching and crimping units, and fibre bonding systems but also decades of accumulated expertise. Even with the right tools, it takes years of development work to get it right.

The result is Finalon™: our proprietary fibre, designed specifically for sweeping applications. For the most demanding use cases, we also offer Finalon+™, a rigid variant which is suitable for e.g. trommel brushes.

Why fibre quality matters

The quality of the fibre affects every aspect of the sweeping outcome:

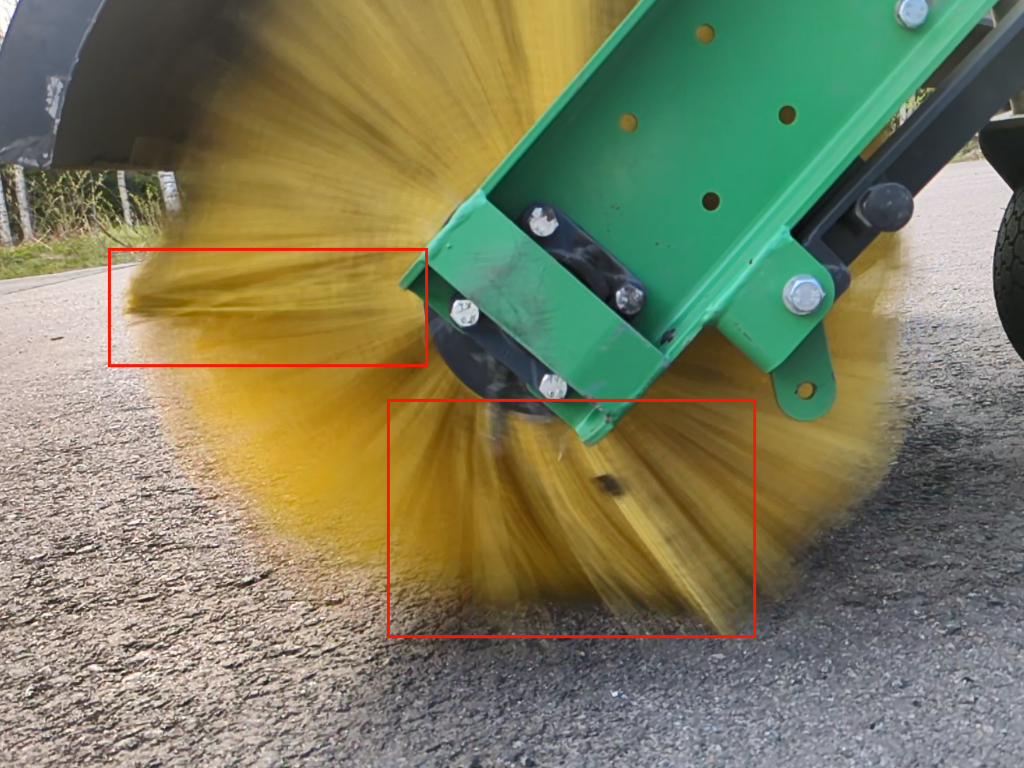

Consistent sweeping motion

The right amount of flexibility allows the brush to bend evenly and sweep material effectively rather than just pushing it forward. You get a cleaner result with fewer passes.

Durability

Strong fibres resist breakage at the base, ensuring long service life even under demanding conditions.

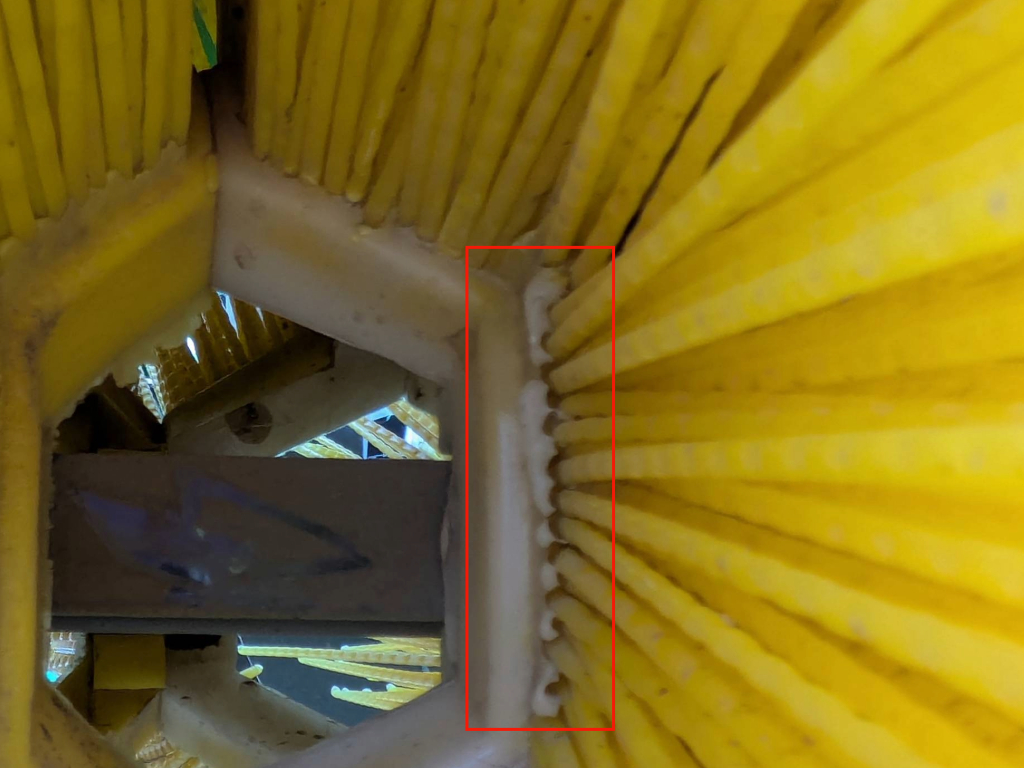

Secure bonding

A well-made fibre bonds seamlessly with the brush core, preventing structural failures and fibre loss in use.

Economic and environmental benefits

Our fibres are designed for maximum longevity and can be incinerated for energy after use, making them both cost-effective and recyclable.

Why we insist on making our own fibres

The answer is simple: because we know what is needed for optimal results. Through decades of research, testing, and customer feedback, we have fine-tuned our fibre to meet real-world demands. That is why machine manufacturers and machine operators around the world choose brushes made with our fibre.